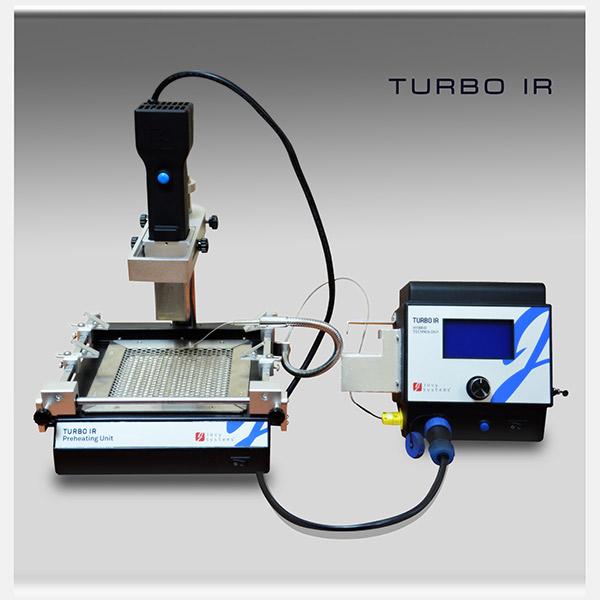

Benchtop Rework station Turbo IR

Turbo IR is Jovy Systems’ first bench top rework station and newest product that utilizes the revolutionary Hybrid heating technology which combines Infrared heating technology as well as Hot Air.

Turbo IR will empower you to catch the train of Hybird technology advances.

With Jovy Benchtop rework station no tough application can stand on your way.

It is designed to offer simple and creative solutions for your sensitive applications.

Jovy Benchtop consists of two main parts; *The Control Unit and*The Preheating Unit.

- Description

- Reviews (0)

Description

Hybrid of quality and innovation

Turbo IR is Jovy Systems’ first bench top rework station and newest product that utilizes the revolutionary Hybrid heating technology which combines Infrared heating technology as well as Hot Air.

Turbo IR will empower you to catch the train of Hybird technology advances.

With Jovy Benchtop rework station no tough application can stand on your way.

It is designed to offer simple and creative solutions for your sensitive applications.

Jovy Benchtop consists of two main parts; *The Control Unit and*The Preheating Unit.

1)The control unit is responsible for adjusting the heating powers of the whole station. The Control unit has a small compact design and doesn’t require a large working space.

– A digital display that can be controlled easily with a simple joystick-push button, to easily select from the options and adjust the power and temperature with one simple move and touch.

– A Powerful (pump) pick up tool up to 120gm lifting power is integrated in the control unit for removing chips and ICs safely.

-Hand-held unit is the part that utilizes the Hybrid Technology and is attached to the control unit .it is a simple, small and smooth unit that can be easily contained in the palm of the hand of the user and yet it’s still light. It can be used freely or it can be attached to the Preheating unit where it can move up or down and back or forth.

– -A handle is integrated with the unit to carry the hand-unit when not in use.

– A push button, integrated in the hand unit, can directly activate the unit.

– 3 compatible nozzles for safe heat distribution without affecting the adjacent components.

– Laser pointer is used for alignment and precision in placing any application and dealing with it.

2) The pre-heating unit which consists of German IR heater to satisfy the basics of a successful rework process.

Pre-heater Unit is one of the best features of Jovy benchtop rework station, as it guarantees uniform preheating of any application. It can run separately or simultaneously with the hand-held unit. A grid (or net) is directly above the Heaters for safety and also to assure the fast and accurate heating of the application.

– XY table is integrated within the preheating unit for a precise placing of any application.

– The Flexi-tube thermocouple that is flexible and moves easily and freely in any direction without any restriction for the safety of the thermocouple and protect from any damage yet is firm to assure precision.

**The unique microprocessor technique with PID Controller make Jovy benchtop rework station has a great output power for both hand-held unit and preheating unit that ensure fast processing and maintain the safety of the components at the same time.

Turbo IR is CE certified

Software features:

Jovy Benchtop rework station can be operated manually or automatically.

The Software of the Turbo IR is simply an elegant interface and graphical wide screen that enable you to:

– Monitor the temperature readings of the process in a real time.

– Save the graphs as reference for any future use.

– Switch between temperature measuring modes (°C / °F).

– Choose your language (Multi-lingual interface)

– Protect PCB or application damage through safety alarm function.

Technical specification of Turbo IR:

| Technical Specification : Hand Held Unit | |

| Dimensions WxHxD | 155 * 175* 210 mm |

| Hand Held unit voltage | 230 volt AC / 5 volt DC for control |

| heating power | 250 watt |

| Main voltage | 220-240 volt AC / 50-60 Hz |

| ambient temperature | 0-40° c |

| Maximum output temperature | 550 ° c |

| IR Wave length | 2-8 µm |

| Laser class | class 2 |

| Nozzle sizes | 20 *20 mm, 10 * 10 mm, 6 *6 mm |

| Technical Specification : Pre-heating Unit | |

| Dimensions WxHxD | 220 * 225 * 405 mm |

| Main voltage | 220-240 volt AC / 50-60 Hz |

| Control voltage | 5 volt DC |

| heating power | 800 watt |

| Maximum PCB size | 200 * 165 mm |

Turbo IR Packing list:

Turbo IR all-inclusive package will grant you complete peace of mind.

1)Control Unit

2)Hand-Held Unit

3)Pre-heating Unit

4)Nozzles 10x10mm , 20x20mm, and 6x6mm

5)Usb cable

6)Pump Set (pump tube+ pump pen+5 nozzles)

7)Power cable

8)Flux 10 cc

9)Reflective Tape 10m

10)Solder paste

11)User Guide

12)Multilingual Start up guide.

13)CD for Jovy’s Videos.

Field of application

Jovy Benchtop Rework Station is specially tailored to cover the potential applications.

1)Smart phone CPU chip removal

2)Smart phone wireless IC removal

3)Power regulator communication PCB

4)Tablet base band removal

5)Smart phone MIC SMD removal

6)Routers

7)CCTV

8)Access control system

9)Automatic Gate system

10)Turnstile

11)barrier Gate

12)Door-phone and intercom system

13)R&D for EMS electronic manufacturing sectors

Warranty of Jovy BenchTop Rework station:

1 Year applied from date of purchase with lifetime full application & technical support

Reviews

There are no reviews yet.